Understanding CMMS: What It Is, Its Uses, and Essential Software Tips

A CMMS is software that helps firms handle maintenance work efficiently. It tracks assets, arranges calendars, and lowers downtime, thereby increasing production. Many businesses rely on CMMS to streamline operations and prevent unforeseen failures. Data about equipment, maintenance, and work orders is kept in CMMS programs. It automates scheduling, inventory management, and other operations, reducing manual work and errors.

CMMS helps businesses properly extend asset life and manage maintenance expenditures. It also assures safety and maintains top equipment condition. Effective CMMS implementation improves company operations and helps save money. Knowing CMMS, its advantages, and best practices helps companies realize its full possibilities. This article investigates CMMS operations and provides general guidelines for efficient use of it.

What Is a CMMS?

A Computerized Maintenance Management System is a program designed to run maintenance operations for companies effectively. It lets teams monitor repairs and complete preventative maintenance by storing information on tools, timetables, and work orders. CMMS replaces manual maintenance records with a digital system, preserving all data in one place. Users of desktops or mobile devices can access it, which simplifies maintenance management by accuracy. CMMS helps to avoid equipment malfunctions by arranging maintenance chores ahead of time.

It also improves reaction time when repairs are needed, avoiding costly downtime. Companies utilize CMMS to increase asset life, minimize maintenance costs, and enhance operational efficiency. The program creates reports on maintenance history and equipment performance that give management insightful information. These analyses enable companies to maximize maintenance plans, make wise judgments, and raise output. Using a CMMS can help to greatly improve efficiency and guarantee that equipment stays in perfect state.

Key Uses of CMMS

CMMS software has various substantial uses across different sectors. It helps organizations maintain machinery, control work orders, and track assets.

- Preventive Maintenance: Routine maintenance for machines and equipment is scheduled using CMMS, therefore preventing unplanned failures. It alerts consumers when services are required, therefore preventing expensive breakdowns, lowering downtime, and increasing operational efficiency for companies in many different sectors.

- Work Order Management: The technology tracks maintenance chores in real-time and sends them to the appropriate experts. It guarantees timely task completion, lowers delays, and improves workflow efficiency, maintaining neat and simplified maintenance operations. It also facilitates managers' better resource allocation and monitoring of development.

- Asset Management: CMMS notes important equipment information like condition, location, and service history. Helping companies maximize asset lifetime, maximize use, and eliminate unplanned failures—which results in cost savings and improved resource management—benefits them.

- Inventory Control: The program tracks supply and spare components, alerting when inventory is low. By preventing repair delays caused by absent components, it guarantees flawless operations and a continuous flow in important maintenance activities.

- Compliance and Safety: CMMS keeps maintenance and inspection records, helping organizations comply with safety laws. It maintains workplace safety, encourages regulatory conformity, and minimizes hazards, providing a secure and legally compliant work environment.

Benefits of Using CMMS

A CMMS system provides several benefits to enterprises. It raises equipment dependability, lowers expenses, and increases efficiency.

- Reduced Downtime: Regular maintenance prevents unanticipated failures and ensures machines' correct operation. It reduces disturbance and maximizes production efficiency by keeping processes running smoothly, eliminating expensive shutdowns, and encouraging general equipment dependability.

- Lower Maintenance Costs: Reducing emergency repairs and increasing equipment life helps CMMS minimize maintenance expenditures. It plans preventative maintenance, therefore avoiding expensive repairs and failures. While increasing operational efficiency and ensuring equipment dependability over time, companies save money on repairs, replacements, and labor.

- Increased Productivity: Service requests and equipment history are quickly accessible to maintenance workers. This allows for faster task completion, better workflow efficiency, and fewer delays, which helps technicians concentrate on important maintenance activities.

- Better Decision-Making: CMMS gives important trend data for maintenance. These realizations enable leaders to make wise decisions, enhance operational performance and economy of cost, streamline maintenance plans, and enable correct use of resources. It also helps to find reoccurring problems and maximize long-term maintenance plans.

- Improved Compliance: Companies must follow safety rules. By tracking compliance records, maintenance logs, and inspections, CMMS guarantees regulatory conformance, lowers risks, and preserves workplace safety standards by effectively controlling these areas.

Essential CMMS Software Tips

Companies should follow the best standards to maximize the performance of CMMS tools. These are some key pointers for properly using CMMS.

- Choose the Right Software: Choose a CMMS program that fits your company. Search for tools for work order tracking, handling assets, and analysis to guarantee seamless maintenance operations and increase effectiveness.

- Train Your Team: Provide comprehensive training so staff members may properly apply the CMMS system. By providing hands-on seminars, user guides, and continuous assistance, you can maximize adoption and reduce maintenance management mistakes.

- Keep Data Updated: Frequent updates of inventory levels, equipment data, and repair records improve Accurate data, track asset performance, guarantee the dependability of the system for planning and decision-making, and aid in optimum maintenance expenditures. It also guarantees timely maintenance procedures, therefore preventing unplanned failures.

- Automate Maintenance Schedules: Use CMMS to automatically plan preventative maintenance. Guaranteeing timely maintenance activities helps prevent equipment malfunctions, lower emergency repairs, and increase operational efficiency.

- Monitor System Performance: Review CMMS indicators and analytics to discover inefficiencies. Use information findings to optimize maintenance plans, increase asset performance, and arrive at educated choices for optimal resource utilization.

- Integrate with Other Systems: To simplify processes, link CMMS with HR, finance, and inventory systems. Integration raises general operating efficiency, coordinates departments, and increases data accuracy.

Conclusion:

CMMS tools are essential for good control of maintenance activities. It aids firms in tracking assets, arranging repairs, and reducing downtime. Good use of CMMS reduces costs, extends equipment lifetime, and increases output. To make use of CMMS, companies should select the suitable program, provide tools to their employees, and maintain accurate data. Automating maintenance schedules and routinely monitoring system performance guarantees perfect operations and aids in preventing unanticipated failures. Long-term success stems from investing in CMMS tools. A good application of this will lead to improved resource allocation, increased maintenance management, and, over time, appreciable cost savings.

Related Articles

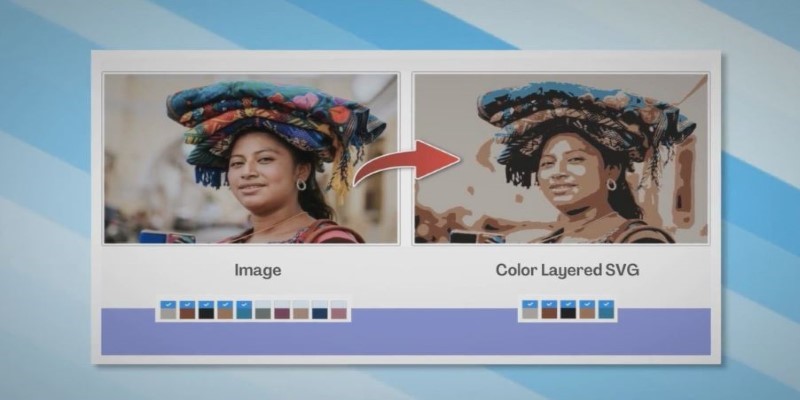

From SVG to PNG: The Ultimate Guide for Converting 2D Graphics into Digital Images

How to Convert JPG to SVG: The Best Methods for Beginners and Experts

Cartoon Effect for Beginners: How to Convert Images with Ease

How to Detect AI-Generated Text and Photos in a World of Digital Deception

Best Image to PDF Converters for Desktop: 6 Top Picks

Top 5 Efficient Ways to Convert WMV to MOV on Windows

How CoverDoc Uses AI to Revolutionize Cover Letter Writing for Job Seekers

How to Easily Print Contracts with ezeep Blue: A Complete Guide

Transform Your Photos into Artistic Sketches with the Best Sketch Editor

The 11 Best CRMs for Small Business: Streamline Your Workflow in 2025

How to Use Scheduling Assistant in Outlook: A Step-by-Step Guide

knacksnews

knacksnews